What size white aluminum oxide can remove the electroplating layer on the copper surface?

The choice of white aluminum oxide model depends on the properties, thickness, and removal efficiency of the electroplated layer.

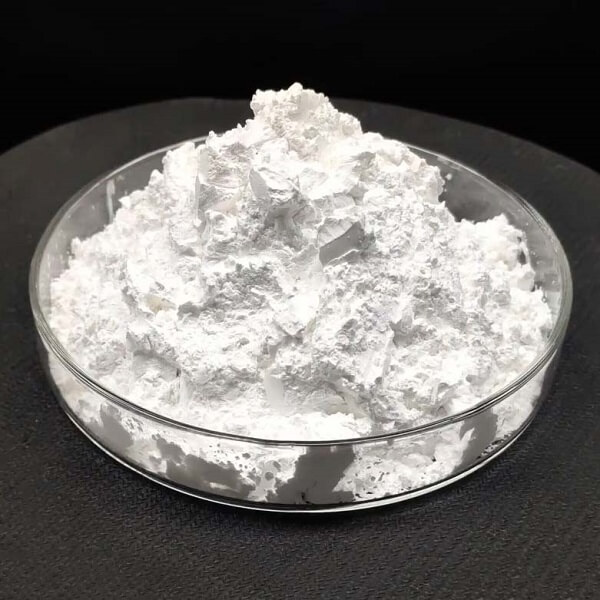

white aluminum oxide can use as an abrasive for surface treatment due to its corrosion resistance, high temperature resistance, and high hardness.

white aluminum oxide particle size sand:

Models: Common ones include F12, F30, F54, F90, F100, F150, F220, etc.

Characteristics: Granular sand is mianly use in the abrasive industry and has good grinding effects. Choosing the appropriate particle size can ensure effective removal of the plating layer while reducing damage to the copper substrate.

white aluminum oxide segment sand:

size: 1-0mm, 3-1mm, 5-3mm, 8-5mm, etc.

Characteristics: Segment sand is usually used for rough surface treatment and is suitable for removing thicker electroplating layers. Due to the large size of the particles, the segmented sand may leave noticeable marks when removing the plating layer, so subsequent treatment is required to achieve a smoother surface.

white aluminum oxide fine powder:

Model: 325-0 mesh, 240-0 mesh, 220-0 mesh, 180-0 mesh, etc.

Features: Fine powder has smaller particle size, which can provide finer grinding effect. Fine powder is a good choice for removing thin and uniform electroplating layers.

white aluminum oxide micro powder:

Models: W63, W20, W15, W10, W7, W5, et

Characteristics: Micro powder has extremely small particle size and can provide very fine grinding effect. If the plating layer is very thin or requires particularly fine treatment, micro powder may be a suitable choice. However, due to the complex processing procedures and high prices of micro powders, their cost-effectiveness needs to be carefully considered.